In the late 1950s, MIT professor Jay Forrester invented the Beer Game, a simple table game simulating the complex task of getting a product from factory to consumer. The game illustrates the challenges of supply chain management, where each link operates as a small business. The game’s key lesson remains relevant: the failure of one link can disrupt the entire supply chain. Decades later, supply chain dynamics have evolved, but the fundamental challenge of ensuring effective communication and coordination among different supply chain facets persists.

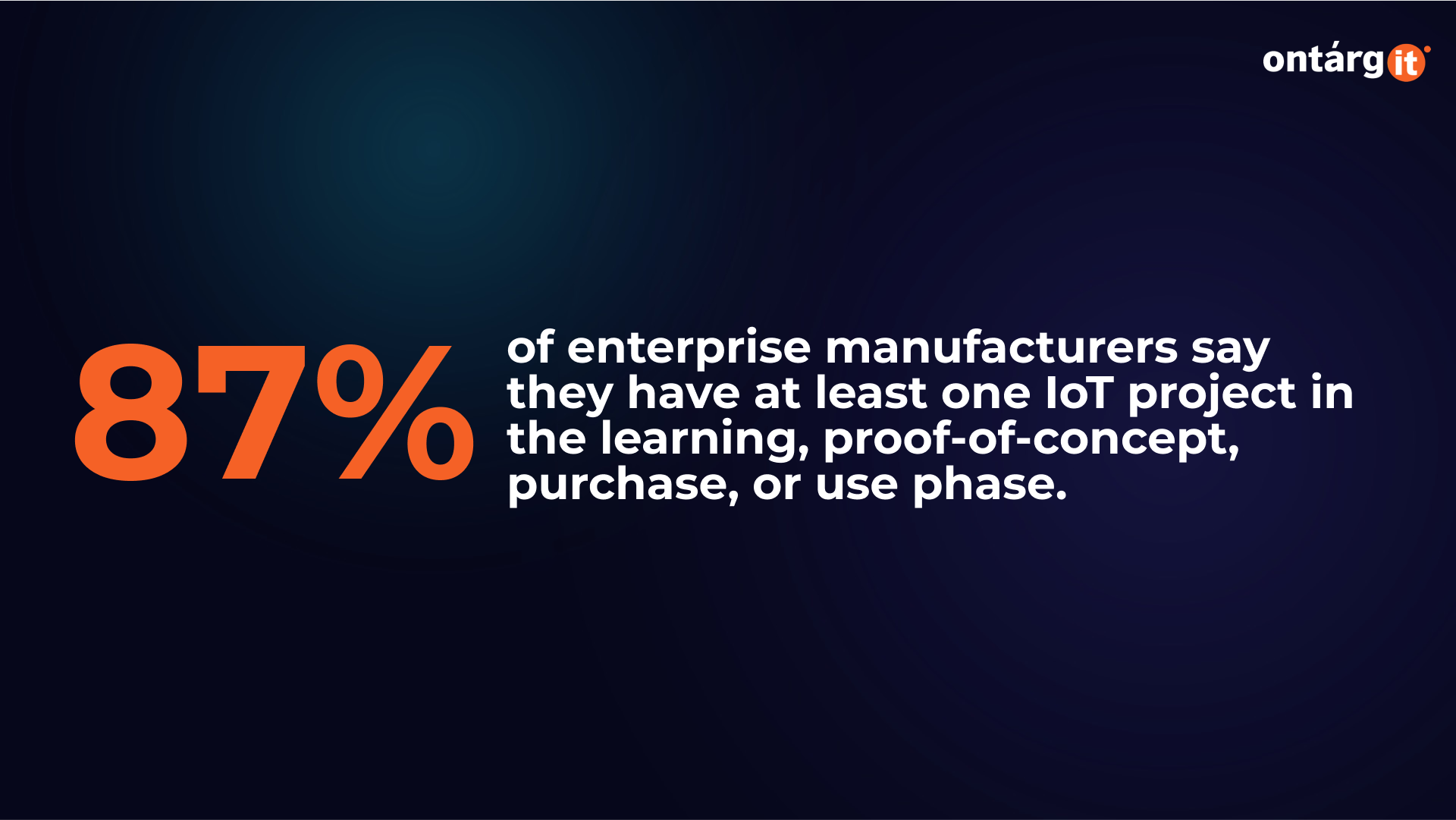

The supply chains of the 20th century grew more sophisticated, leading to the development of enterprise resource planning (ERP) systems. These systems, while making businesses more efficient, became monolithic and struggled to keep pace with modern industry demands. Soon, it is expected that at least 50 percent of large global companies will adopt AI, advanced analytics, and IoT in supply chain operations, resulting in significant industry shifts and benefits.

What Makes an Intelligent Supply Chain?

Improve Your Supply Chain with Real-Time Insights

Assessing your ERP’s challenges and opportunities requires a comprehensive view. Often, different experts examine each part of the supply chain independently, leading to inefficiencies. A siloed system means siloed data, impacting inventory control, fulfillment, employee productivity, and forecasting. An intelligent supply chain delivers integrated, real-time metrics, removing guesswork and optimizing effectiveness. Even small improvements can significantly boost the bottom line.

Get 24/7 Inventory Awareness

The speed of technology means available inventories can change rapidly. Small market shifts can lead to sudden demand increases, and without an intelligent supply chain, you risk inadequate inventory and missed sales. Supply chain inventory visibility (SCIV) applications monitor global inventory, ensuring timely and accurate information across warehouses, stores, and third-party shipping companies. This visibility is central to delivering the right product at the right time at the best price.

Increase Efficiency with Instant Metrics in Production Planning

A real-time, comprehensive view of your supply chain is critical in production planning. An intelligent supply chain enables accurate resource allocation, product mix determination, employee scheduling, and production capacities in real-time. This leads to increased efficiency, higher product quality, and reduced costs and waste. An ERP solution connecting systems through the cloud is essential for optimizing operations.

Optimize Fulfillment to Satisfy Customers

Optimizing fulfillment requires efficient inventory movement. A modern ERP automatically determines the optimal shipping point based on factors like geolocation, inventory, and sell-through rates. This improves shipment-to-order KPIs, ensuring multiple items ordered by a customer are sent in a single shipment. Automation of tasks like invoicing frees employees to focus on strategic work.

Boost Uptime with IoT and Predictive Maintenance

Maintenance is often an afterthought, but it significantly impacts productivity. Poor maintenance strategies can reduce plant capacity by 5 to 20 percent. IoT and predictive analytics can slash downtime by proactively managing asset maintenance. Smart parts and IoT sensors detect near-failure conditions, initiating maintenance before breakdowns occur, ensuring continuous operation.

Resolve Issues Proactively with AI and Machine Learning

AI and machine learning are revolutionizing supply chain logistics by processing vast amounts of data and making decisions based on it. Predicting future supply chain demands with AI can reduce freight costs, improve supplier delivery performance, and minimize supplier risk. Optimization of raw materials and production management is another key benefit of AI.

Incorporate Augmented and Mixed Reality

Augmented reality (AR) and mixed reality are increasingly used in supply chain management. These technologies reduce costs in the picking process with vision-based object recognition and navigation devices. AR is also used for training and equipment maintenance, reducing errors and improving problem-solving speed.

Ensure Customer Satisfaction with Product Delivery Automation

In an era of high customer expectations, a seamless, automated supply chain is essential. Vendors need a predictive overview of production, inventory, shipping, and profitability to ensure on-time delivery and product availability. An integrated ERP handles the personalized, end-to-end journey customers demand, meeting their expectations for quick and reliable delivery.

Empower Employees with End-to-End Visibility

Modern supply chain ERPs free employees to make better decisions with real-time data and predictive insights. End-to-end visibility into equipment operation, inventory, and production processes empowers employees to collaborate and respond quickly to demand changes and disruptions. This visibility provides a significant competitive advantage, allowing businesses to outperform competitors.

Frequently asked questions

Build a Customer-Centric Supply Chain

Every link in the supply chain leads to the customer. Incorporating machine-learning technologies allows for smarter business processes, equipping employees with predictive analytics. This transforms the supply chain into a multichannel delivery system focused on customer experience. Manufacturers can decrease product costs and offer better prices, responding more effectively to customer wants for future products and services.

Ensure Transparent and Fast Delivery

A key component of a positive customer service experience is the transparent and fast delivery of products. Customers want their goods delivered quickly and in good condition, and they want to know where their products are every step of the way. A fully integrated, modern ERP can handle this personalized, end-to-end journey, ensuring customer satisfaction.

Why Microsoft Dynamics 365 Supply Chain Management?

When selecting an ERP, it’s essential to choose a system that fits your current needs and can grow with your business. Microsoft Dynamics 365 Supply Chain Management combines the best of old and new ERP worlds, offering scalability, flexibility, and intelligence. It integrates seamlessly with existing systems and tools like Microsoft Office 365 and HoloLens, promoting smarter business processes infused with AI and Microsoft Power BI.

Dynamics 365 enables continuous predictions and proactive execution, improving collaboration, control, and efficiency. It offers complete visibility into warehousing and transportation, reducing costs and driving customer satisfaction. The system also supports predictive maintenance using IoT and machine learning, decreasing downtime and enhancing operational efficiency.