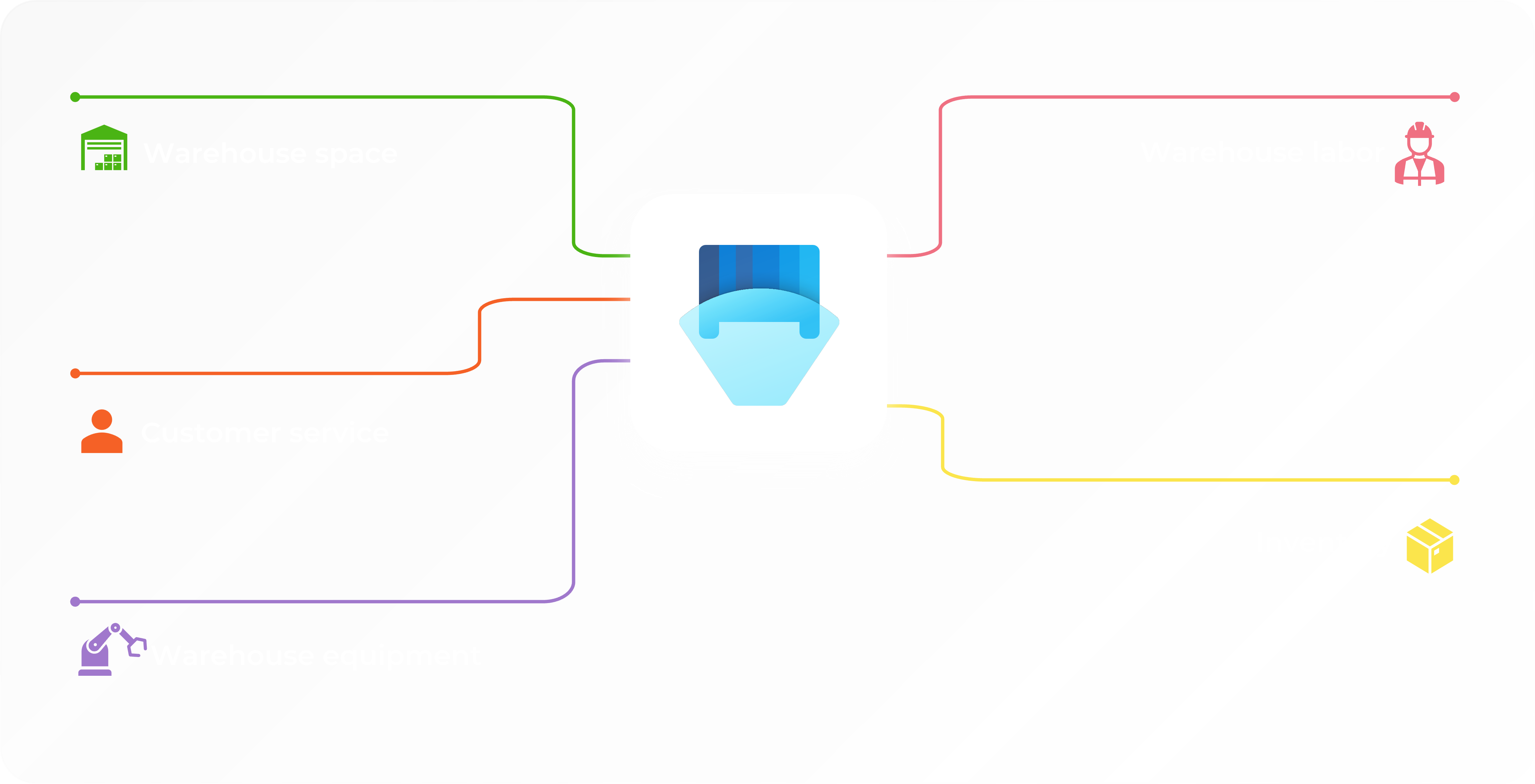

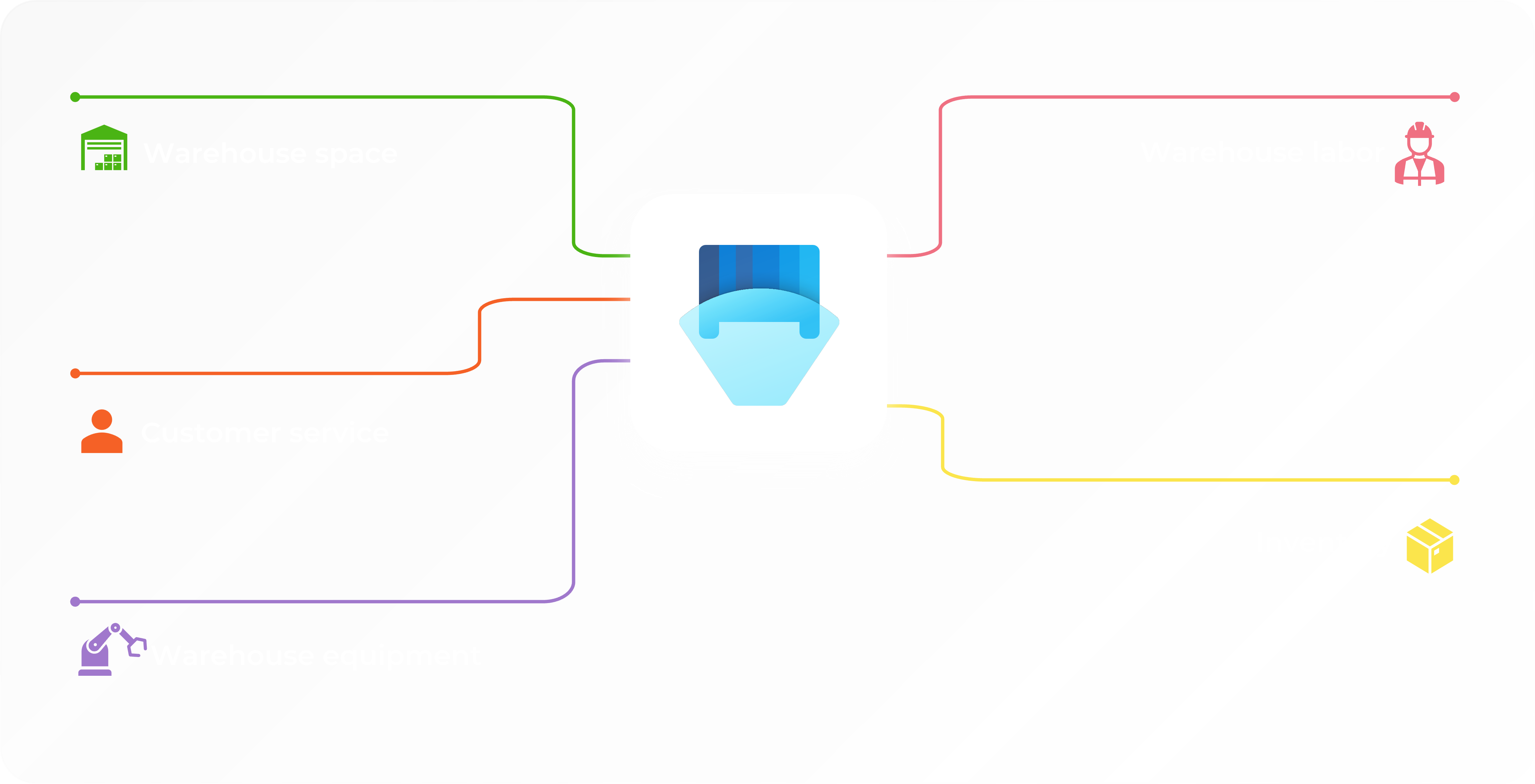

Warehouse components

Why implement warehouse management system?

Key functionality

Dynamics 365 warehouse management system benefits

Explore Dynamics 365 Warehouse Management System on YouTube

In many ERP implementation projects, companies do not use the product’s capabilities to the fullest. Mainly focusing on accounting process. In particular, they do not usually consider optimization of warehouse operations. At the same time benefits of warehouse management system module in Dynamics 365 is a business solution that will create the prerequisites for further growth, innovation and stable work of your company.

Discover the latest features and opportunities of Dynamics 365 Warehouse Management System. Visit our YouTube channel for in-depth insights.