Manufacturing in 2024 is all about innovation, which is the driving force behind building economic capacity, bolstering workforces, and generating growth opportunities. Today, the manufacturing industry trend is undergoing a once-in-a-century transformation driven by changing consumer demands, labor challenges, supply chain disruptions, technological advancements, and sustainability demands. Since the Industrial Revolution, the industry has transformed into a much more complex and dynamic place. It’s time for companies to leverage cutting-edge tools and solutions to streamline operations, increase efficiency, and deliver an outstanding customer experience.

As we enter the age of innovation, let’s explore 4 trends in manufacturing for 2024 and what they may bring us.

Manufacturing is no longer simply about making physical products. Changes in consumer demand, the nature of products, the economics of production, and the economics of the supply chain have led to a fundamental shift in the way companies do business.

Empowering the сonnected workforce

Modern cloud solutions can streamline operations, boost efficiency and productivity, and create a safer, more engaged workforce from the front office to the factory floor.

Manufacturers face unique challenges in their operations, and new capabilities and updates for the workforce aim to address these challenges. These updates help streamline frontline operations, enhance communication and collaboration, improve the employee experience, and strengthen security across shared devices. Additionally, AI is utilized to optimize manufacturing processes and make them more flexible and reconfigurable.

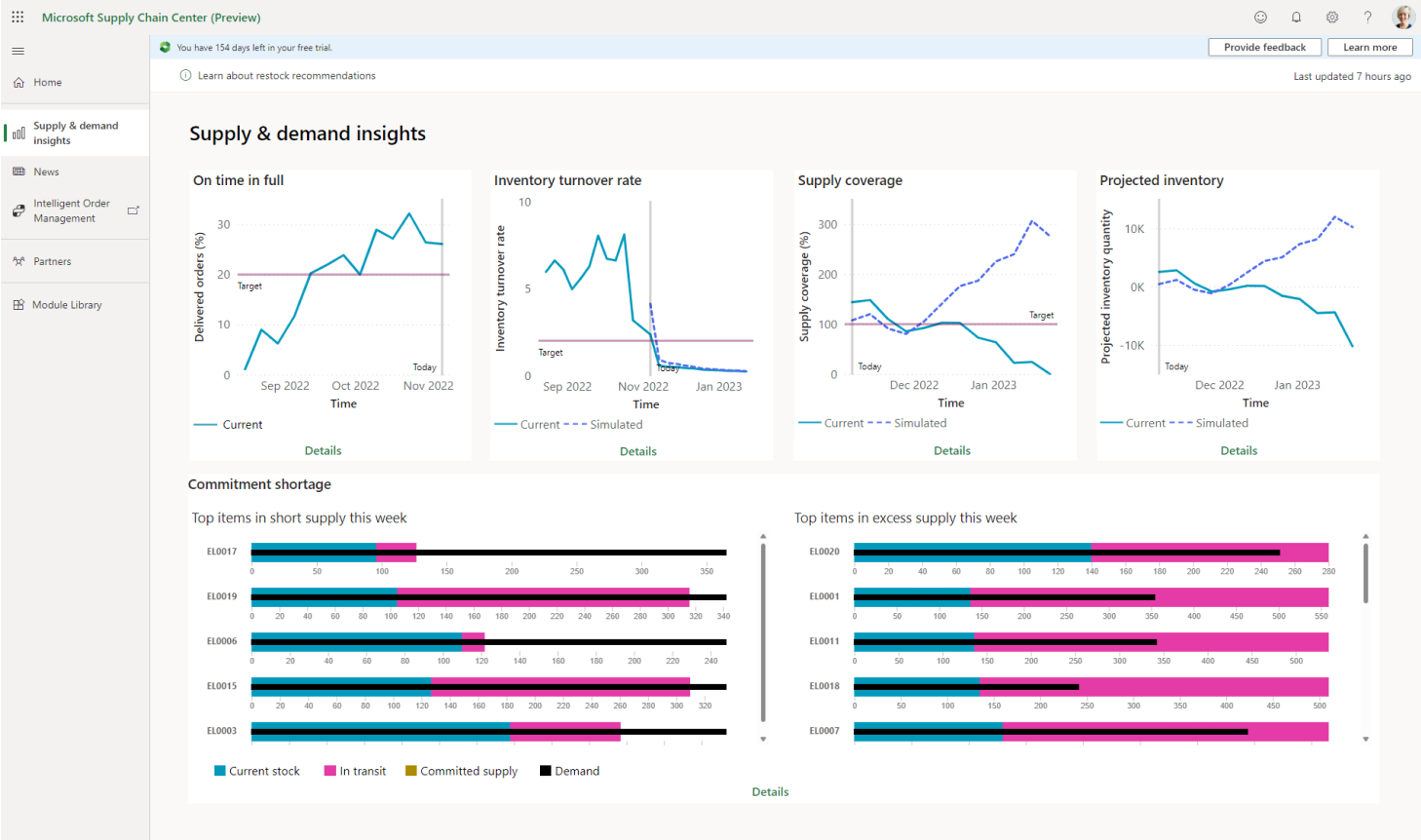

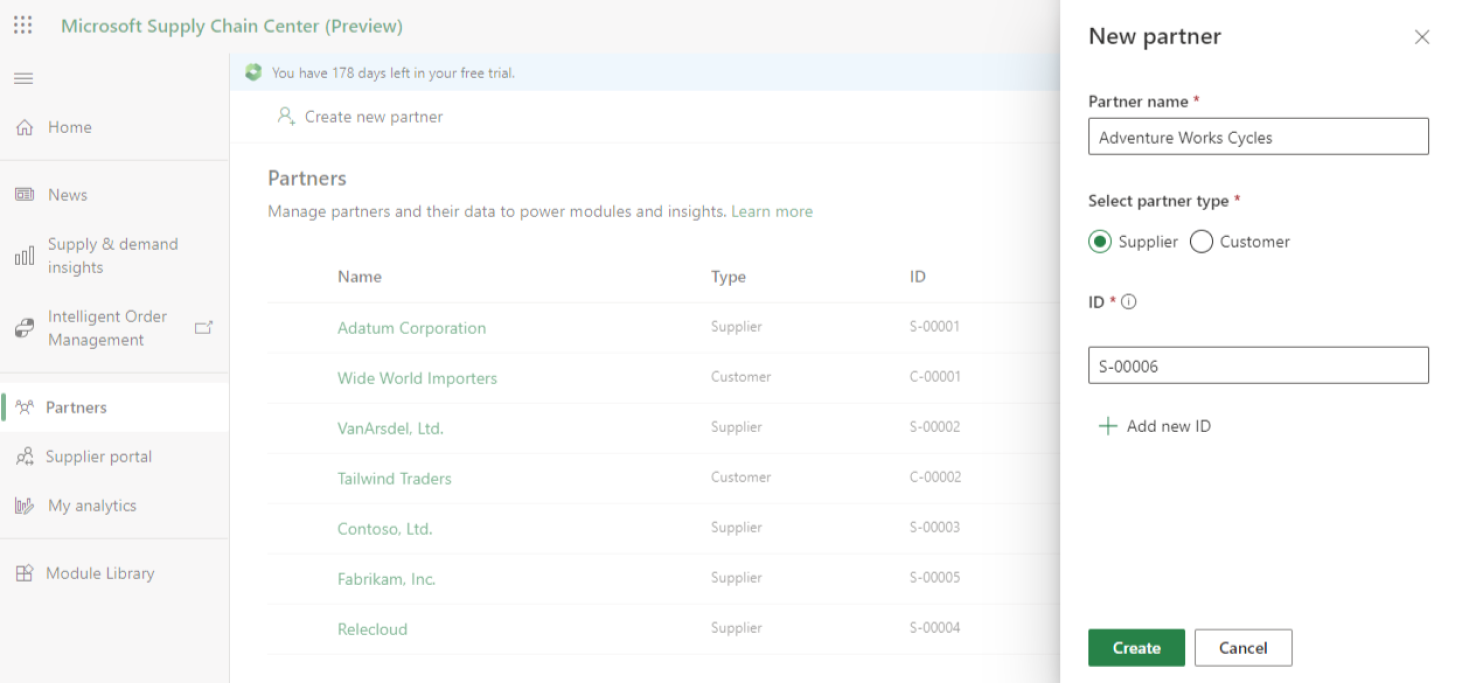

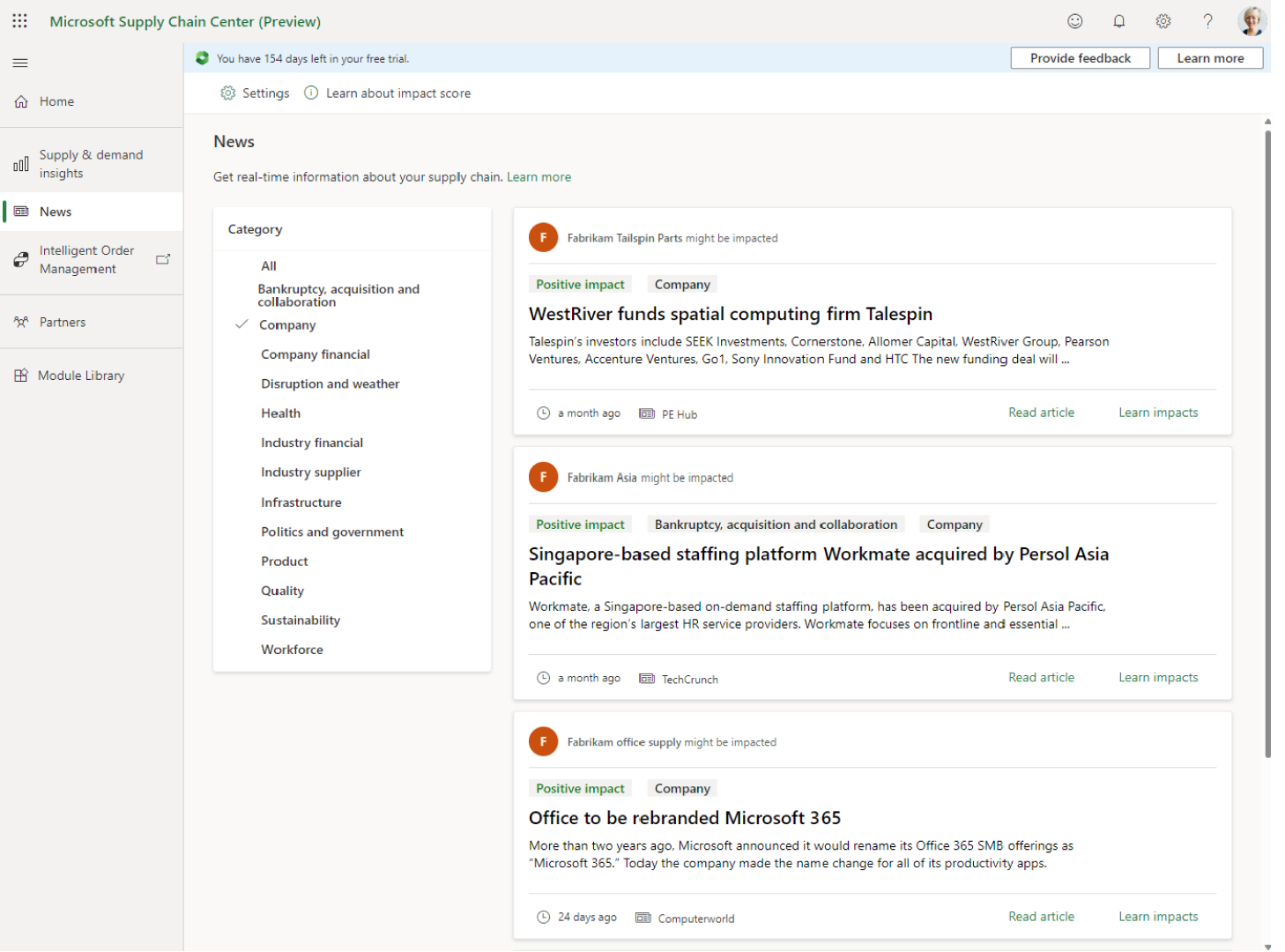

Building agile supply chains

Companies are struggling to keep up with the complexity and speed of supply chain disruptions.

With Microsoft’s advanced Supply Chain Platform and Supply Chain Centers, companies can confidently reduce supply chain risk while keeping their existing systems intact. These solutions provide a highly customizable command center, tailored to meet the unique needs of each business.

On top of that, Microsoft Dynamics 365 Copilot provides real-time predictive insights using generative AI across materials, inventory, distribution networks, and more, enabling businesses to avoid potential disruptions.

People and AI working together

Integrating AI into manufacturing operations can offer significant benefits in terms of predictive maintenance. By analyzing historical data, AI can predict when a machine is likely to fail or require maintenance. This proactive approach enables companies to prevent costly downtime and prolong the lifespan of their equipment.

One of the most significant changes in manufacturing has been the rise of intelligent factories. Imagine an industrial ecosystem connected to a common virtual space that allows everyone to visualize and interact with complex processes in real time, with real-world data.

The industrial metaverse, built with foundational technology like AI, Digital Twins, Mixed Reality, ML, and Cloud-To-Edge is changing how companies run and manage their business by delivering immediate value through remote operations and skilling, AI process and asset optimization and robotics, automation, and autonomous operations.

Manufacturing companies can use blockchain to track goods in real-time, reducing the risk of lost or stolen items and improving delivery times. The technology can also help with customs clearance, reducing the need for manual paperwork and speeding up the process.

Similarly, the Industrial Metaverse is creating new opportunities to make product engineering more collaborative and immersive. This enables manufacturing companies to reduce and accelerate time-to-market in an increasingly competitive environment.

Microsoft’s commitment to immersive experiences that support manufacturers and frontline workers continues with bringing Windows 11 to HoloLens 2, enhancing security, and offering the latest tools for developers.

Industrial Internet of Things (IIoT), where interconnected devices are used in manufacturing and industrial settings to collect data – data that can then be used to enhance the manufacturing process.

Sensors are a prime example of these interconnected IIoT devices. Data gathered from sensors on factory machines can help manufacturers understand how machines are performing, optimize the maintenance process, reduce machine downtime, and even predict when things will go wrong.

Sustainability is more important than ever

Sustainability is a top priority for manufacturers who are adopting eco-friendly practices and implementing initiatives, such as using renewable energy sources, adopting circular economy principles to reduce waste, and optimizing production processes to minimize environmental impact.

Through technology like the Microsoft Cloud for Sustainability and a rich partner ecosystem, Microsoft is building a critical foundation for an energy-efficient and sustainable future.

Many manufacturers are facing the urgent situation of rising energy costs on the factory floor and the production plant, which is why Microsoft is working with partners and customers to prioritize top use cases that will help manufacturers gain visibility into where energy loss is occurring and triage the issue through targeted assessments.

These are some of the exciting innovations happening today to help build a stronger, more resilient, and more sustainable tomorrow.

These trends can affect different manufacturing sectors at different rates. To determine the speed and intensity of the coming shifts in a particular sector, companies should consider factors including the extent of regulation, product size and complexity, and the sector’s level of digitization.