Dynamics 365 Supply Chain Management has a new module – Asset Management, designed to automate the processes of maintenance and repair of equipment – MRE for short.

With this module you can effectively solve tasks directly in the Dynamics 365 system without using side solutions like Project Management module and making extra steps to integrate results.

Asset management module

The concept of enterprise asset management (EAM) involves the management of tangible assets throughout the entire life cycle from acquisition to write-off.

This includes not only repair and maintenance, but also the processes of buying and selling assets, accounting spare parts, depreciation, maintenance technicians managing.

So, the EAM system must answer this types of question:

About assets:

About the service:

Why is this system needed, and why is it important for business?

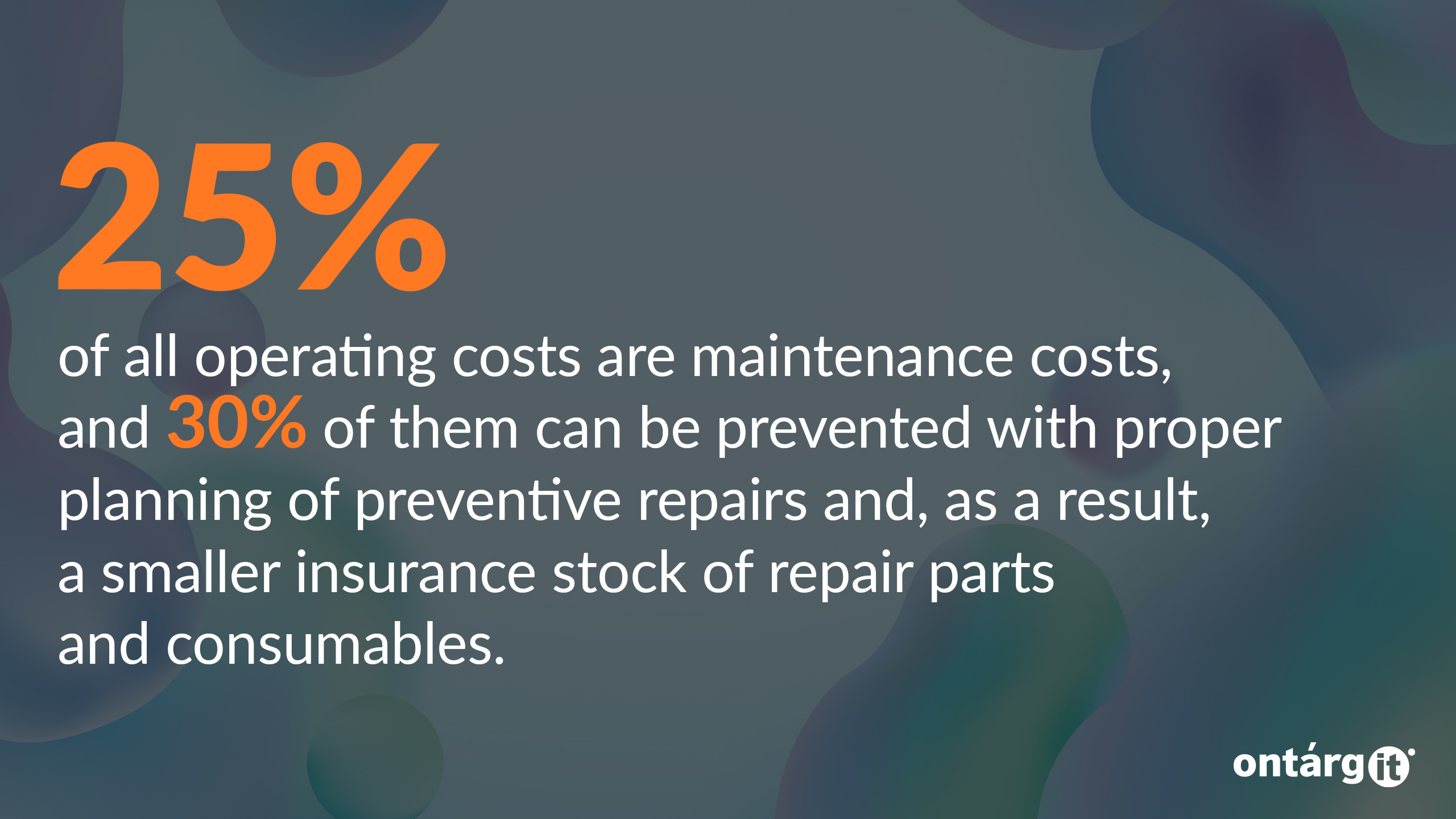

When it comes to maintenance and repair, we should mention two important factors affecting operating activities cost.

The first is equipment downtime which leads to the inability of production to deliver products on time (for example, a deviation from planned production dates or suboptimal productivity).

The second is “reactive service” – a situation where a response to equipment failure and its repair takes place after the production process fails and work stops. In most cases it happens unexpectedly and often leads to overtime service technician work and urgent purchase of spare parts, often at an inflated price, and delivery overpayment.

If we pay more attention to this, we will find out that these factors affect both direct and indirect costs.

Service models

There are several conceptual service models. These models are often implemented in work gradually, so the response to an incident and the useful life of assets eventually increase.

The first two models are the most common:

- Reactive is the simplest model. You conduct maintenance and repair only when assets fail. Without causing significant problems for the company, this approach only can be used if the equipment is not crucial and can be easily repaired.

- Preventive model allows you to reduce the risk of future failures in work with preventive maintenance. Maintenance is planned according to the type of equipment and the features of its operation.

- Reliability Centered Maintenance is the concept that the goal of maintenance is not to keep each piece of equipment in perfect condition, but to ensure the reliability of production processes that are important to the company. For these purposes, you can connect equipment sensors to the industrial Internet of things to remotely monitor its condition. Maintenance is not conducted at fixed intervals, such as once a month, but in the case of significant deviations from “normal” performance or thresholds (for example, every 10 000 hours of operation).

- The latest – predictive model – is based on a daily analysis of the state of the equipment and previously provided history of its maintenance. Information about previous problems in operation and the factors which influence are considered – the system will be able to predict future failures and plan appropriate maintenance work. To implement this model, which operates with the help of machine learning methods, you need to collect data on the factors that affect the equipment work in your company.

Asset management in Dynamics 365

Asset lifecycle management is closely related to other modules of the ERP system:

This allows you to plan the purchase, repair and modernization of equipment, control costs, ensure maximum continuity of production, and effectively manage budgets.

When using the Dynamics 365 Asset Management system, the company receives the following benefits:

Flexible integration

Complex maintenance, commissioning, and asset upgrades require more detailed planning, control, and accounting, and all of this is provided in the Asset Management module.

In addition, Microsoft offers hardware integration through Azure IoT Central.

This product allows you to swiftly deploy a cloud infrastructure and set up the transmission of the necessary telemetry. The program receives signals from the equipment in real-time, for example, about the speed of operation or the equipment temperature, without overloading the ERP system. When a selected indicator is exceeded (for example, a critical temperature), IoT central sends a signal to the Dynamics 365 Asset Management module to create an incident, followed by the appointment of a service specialist for diagnostics.

Assets are a crucial part of a business. A clear understanding of their condition, production capabilities, and the ability to ensure the continued operation of assets on time largely determines cost of operating and your ability to work continuously.

Therefore, with Microsoft Dynamics 365 Asset Management, you can achieve the highest possible uptime of assets, their efficient operation, and predictability in use.