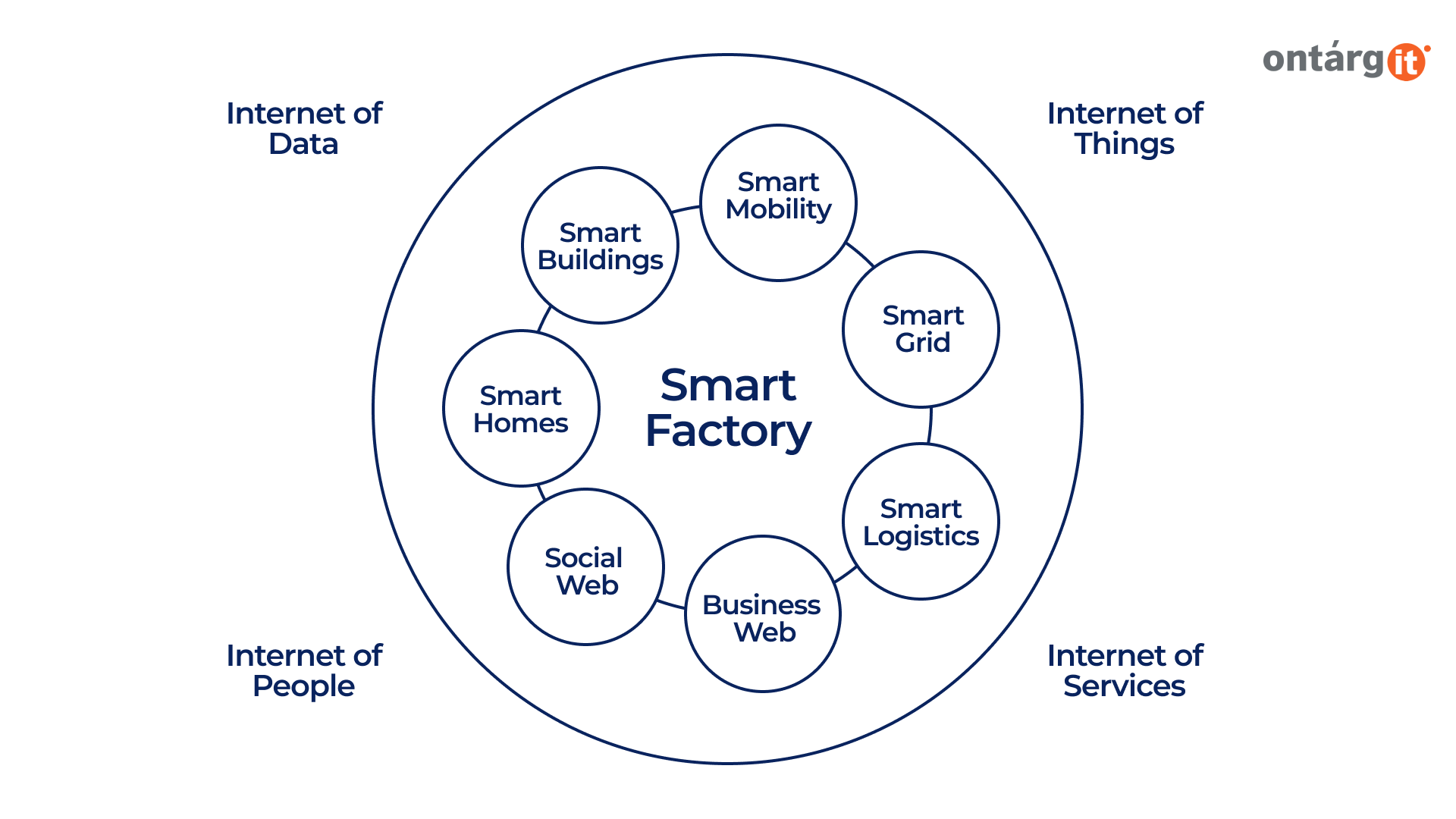

Agile manufacturing represents a significant paradigm shift in industrial production, driven by the integration of cutting-edge technologies like the Internet of Things (IoT), artificial intelligence (AI), and advanced robotics. This technological infusion is transforming traditional factories into “smart factories,” which are benchmarks of efficiency and productivity due to their digital capabilities.

The Rise of the Smart Factory

At the core of smart factory operations are technologies such as IoT and AI, which enable factories to achieve exceptional levels of operational efficiency. These technologies facilitate the creation of a fully integrated environment where machines and systems are interconnected and capable of predictive analytics. This integration leads to enhanced production metrics including increased throughput, reduced costs, and improved safety and sustainability practices.

As the smart factory model becomes more prevalenAgile manufacturing represents a significant paradigm shift in industrial production, driven by the integration of cutting-edge technologies like the Internet of Things (IoT), artificial intelligence (AI), and advanced robotics. This technological infusion is transforming traditional factories into “smart factories,” which are benchmarks of efficiency and productivity due to their digital capabilities. The Rise of the Smart Factory At the core of smart factory operations are technologies such as IoT and AI, which enable factories to achieve exceptional levels of operational efficiency. These technologies facilitate the creation of a fully integrated environment where machines and systems are interconnected and capable of predictive analytics. This integration leads to enhanced production metrics including increased throughput, reduced costs, and improved safety and sustainability practices. As the smart factory model becomes more prevalent, companies are shifting from traditional pilot projects to comprehensive strategies that embed digital technologies into the heart of their operations. According to industry reports, a substantial proportion of manufacturing firms have already implemented or are in the process of adopting smart factory strategies. This move has resulted in a significant increase in connected assets, optimizing operations and resource allocation.t, companies are shifting from traditional pilot projects to comprehensive strategies that embed digital technologies into the heart of their operations. According to industry reports, a substantial proportion of manufacturing firms have already implemented or are in the process of adopting smart factory strategies. This move has resulted in a significant increase in connected assets, optimizing operations and resource allocation.

Infrastructure Transformation in Manufacturing

The transformation towards smart factories is marked by a pivotal shift from traditional on-premise data handling to the adoption of cloud-based platforms, such as Dynamics 365 Supply Chain Management. This strategic move accommodates the vast amounts of operational data generated daily, enabling manufacturers to scale their operations and enhance overall security. Dynamics 365, in particular, plays a crucial role in streamlining supply chain processes by integrating data across the network. This integration allows for more sophisticated management of the data influx and provides powerful tools for real-time data analysis and decision-making. By leveraging these advanced cloud-based solutions, manufacturers can drive significant improvements in operational efficiency and responsiveness to market changes.

Leveraging Data for Strategic Advantage

In the context of agile manufacturing, data acts as a crucial asset. Manufacturers employ sophisticated data refineries to process and convert real-time data from factory operations into actionable insights. This shift not only requires technological upgrades but also a cultural change within organizations. IT and operational technology (OT) teams increasingly collaborate to harness the power of data, fostering a culture of continuous improvement and innovation.

Addressing the Skills Gap with Smart Recruitment

Smart factories are also innovatively addressing the industry-wide challenge of a skilled labor shortage. By attracting a younger, tech-savvy workforce and providing training with advanced digital tools like augmented reality and mixed-reality headsets, manufacturers are enhancing employee engagement and operational productivity. These training tools allow workers to perform complex tasks with higher precision and confidence from the outset, significantly reducing the learning curve.

Strategic Collaborations for Enhanced Manufacturing

The transition to smart manufacturing necessitates not only profound internal transformations but also strategic alliances with technological leaders. Collaborations with industry giants such as Microsoft, leveraging platforms like Dynamics 365 Field Service, provide critical infrastructure and services that integrate advanced manufacturing technologies into production processes. Dynamics 365 Field Service enhances these partnerships by offering tools that optimize field operations through improved resource scheduling, equipment maintenance, and real-time communication. Such synergies are vital for manufacturers to remain competitive in a rapidly evolving digital landscape, enabling them to expand their operational capabilities and effectively prepare for future technological advancements.

In conclusion, the evolution of agile manufacturing into smart factories marks a transformative era in the industrial sector. This shift is characterized by enhanced connectivity, the adoption of cloud-based infrastructures, and a strategic focus on data-driven decision-making. By embracing these advancements and leveraging modern cloud solutions, manufacturers are set to significantly improve operational efficiency and maintain competitiveness in the global marketplace.