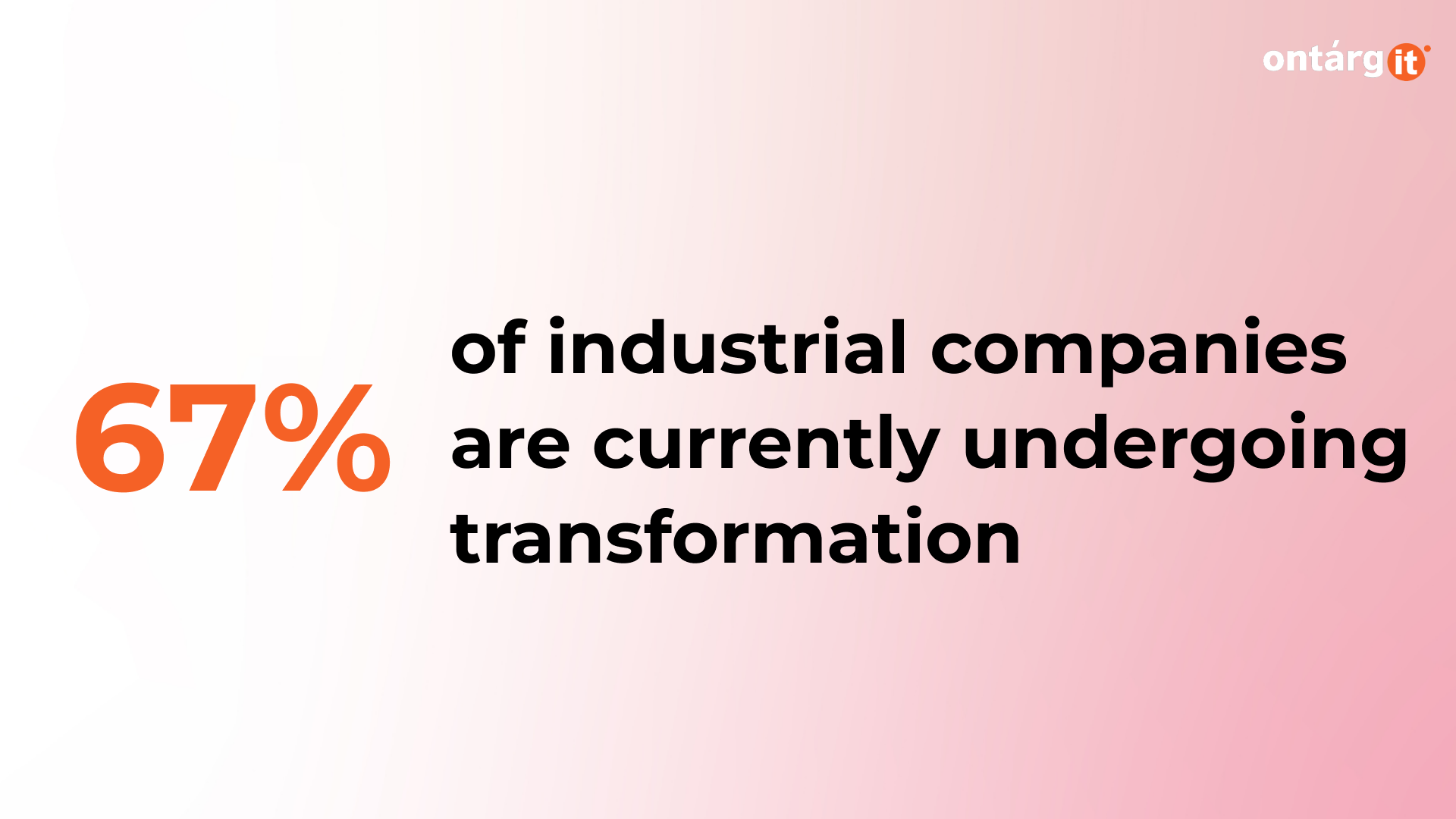

The manufacturing industry is entering a new era of transformation, driven by technological progress and the growing demand for flexibility. Facing ever‑changing global challenges, companies are increasingly adopting innovative software solutions that reshape traditional processes and pave the way for greater efficiency, sustainability, and reliability.

In this article, we will examine key trends in manufacturing development that already reflect reality in 2025.

Table of Contents

Intelligent Agents and AI Automation

Artificial intelligence is actively transforming the manufacturing landscape. According to a Deloitte study, 93% of companies see AI as a key driver of growth and innovation in 2025. Its adoption spans a wide range of areas: from intelligent manufacturing and product improvement to strategic planning and business model selection.

Currently, 51% of all AI deployments in manufacturing are focused on innovative production, where technologies are applied to enhance process automation, improve quality, and reduce downtime.

As the next stage of the digital revolution unfolds, the Internet of Things in manufacturing is transforming production lines into innovative, flexible systems that can automate processes, optimize resources, and significantly enhance overall productivity.

This approach to IoT is already reflected in advanced solutions. One example is Microsoft Dynamics 365 ERP, which integrates data from IoT sensors, smart meters, and production systems to create a comprehensive picture of energy consumption across all facilities. The data flows directly into Microsoft Sustainability Manager, where built-in AI analytics identify inefficiencies, evaluate performance, and offer optimization scenarios. This enables manufacturers to track carbon emissions in real time and confidently achieve their sustainability goals.

Decentralized Manufacturing

Under the pressure of inflation, geopolitical instability, and growing demands for environmental, social, and corporate governance (ESG) responsibility, manufacturing companies are increasingly moving toward decentralized models. By locating production in different regions, they reduce transportation costs, respond more quickly to local market needs, and enhance supply chain resilience.

Case Study: Enerjisa Üretim (Turkey)

The largest private electricity producer in Turkey, Enerjisa Üretim, operates 29 power plants and has replaced its outdated asset management system with Microsoft Dynamics 365, gaining a modern solution to manage the full lifecycle of more than 312,500 assets.

“Data about our equipment is key to operational efficiency. Asset management capabilities in Dynamics 365 extend the service life of critical infrastructure assets. Using real‑time data and advanced analytics, we can predict equipment failures before they occur.”

— Alper Serçe, Deputy CEO of Enerjisa Üretim

By leveraging Dynamics 365 and Azure, Enerjisa improved operational efficiency, reduced costs, and enhanced employee engagement. The integration of asset management, IoT, and Azure Digital Twins enables real-time analytics, predictive maintenance, and improved equipment reliability. Unified data and processes ensure coordinated operations across distributed sites, setting new standards for efficiency in the energy sector.

Green Software for Sustainable Development

Sustainability in manufacturing is increasingly moving beyond physical processes, with software solutions playing a growing role. In 2025, the focus shifts to creating and implementing digital tools that help manufacturers achieve carbon neutrality, reduce waste, and optimize energy consumption.

A vivid example of this approach is the integration of Microsoft Dynamics 365 ERP and Sustainability Manager within the Microsoft Cloud for Sustainability. This solution provides manufacturers with real‑time data, intelligent analytics, and automated monitoring, enabling large‑scale improvements in business sustainability.

Dynamics 365 ERP collects energy consumption data from IoT sensors, smart meters, and production systems, providing a comprehensive view of energy use across all sites. This data flows into Microsoft Sustainability Manager, where AI identifies inefficiencies, evaluates performance, and suggests optimization measures. Such a comprehensive approach ensures real-time carbon emissions control, helping to achieve strategic sustainability objectives confidently.

Conclusion

The manufacturing industry in 2025 stands on the verge of a large‑scale transformation. Intelligent agents, automation, IoT, decentralized production, and green software are no longer future trends — they are becoming integral parts of the strategies of leading companies.

Solutions like Microsoft Dynamics 365 bring together data, processes, and people in a single digital ecosystem, ensuring transparency, sustainability, and high efficiency at all levels. Companies that adopt these technologies today gain a competitive advantage, as they adapt more quickly to market changes, utilize resources more efficiently, and move steadily toward sustainable growth.

In the accelerating digital revolution, flexibility, technological innovation, and environmental responsibility are the keys to success for manufacturers in the new decade.