In today’s volatile industrial landscape, ERP planning has evolved from a simple back-office requirement into the central “nervous system” of the manufacturing enterprise. The core of this process is the seamless integration of sales, inventory, and production into a single source of truth.

Microsoft Dynamics 365 Supply Chain Management stands out as a market leader by offering specific capabilities that address the most complex challenges of modern supply chains. Ultimately, D365 SCM empowers manufacturers with the scalability, visibility, and intelligence needed to maintain a competitive edge in a globalized market.

ERP means Enterprise Resource Planning

In the complex ecosystem of modern manufacturing, planning serves as the vital link between abstract market demand and physical factory execution. It is the strategic discipline that transforms raw data into a synchronized flow of materials, labor, and machine capacity, ensuring that resources are never idle yet never overstrained.

By establishing a clear roadmap for every component and process, planning minimizes waste, stabilizes operational costs, and provides the agility necessary to pivot in a volatile global market, making it the definitive backbone of organizational profitability.

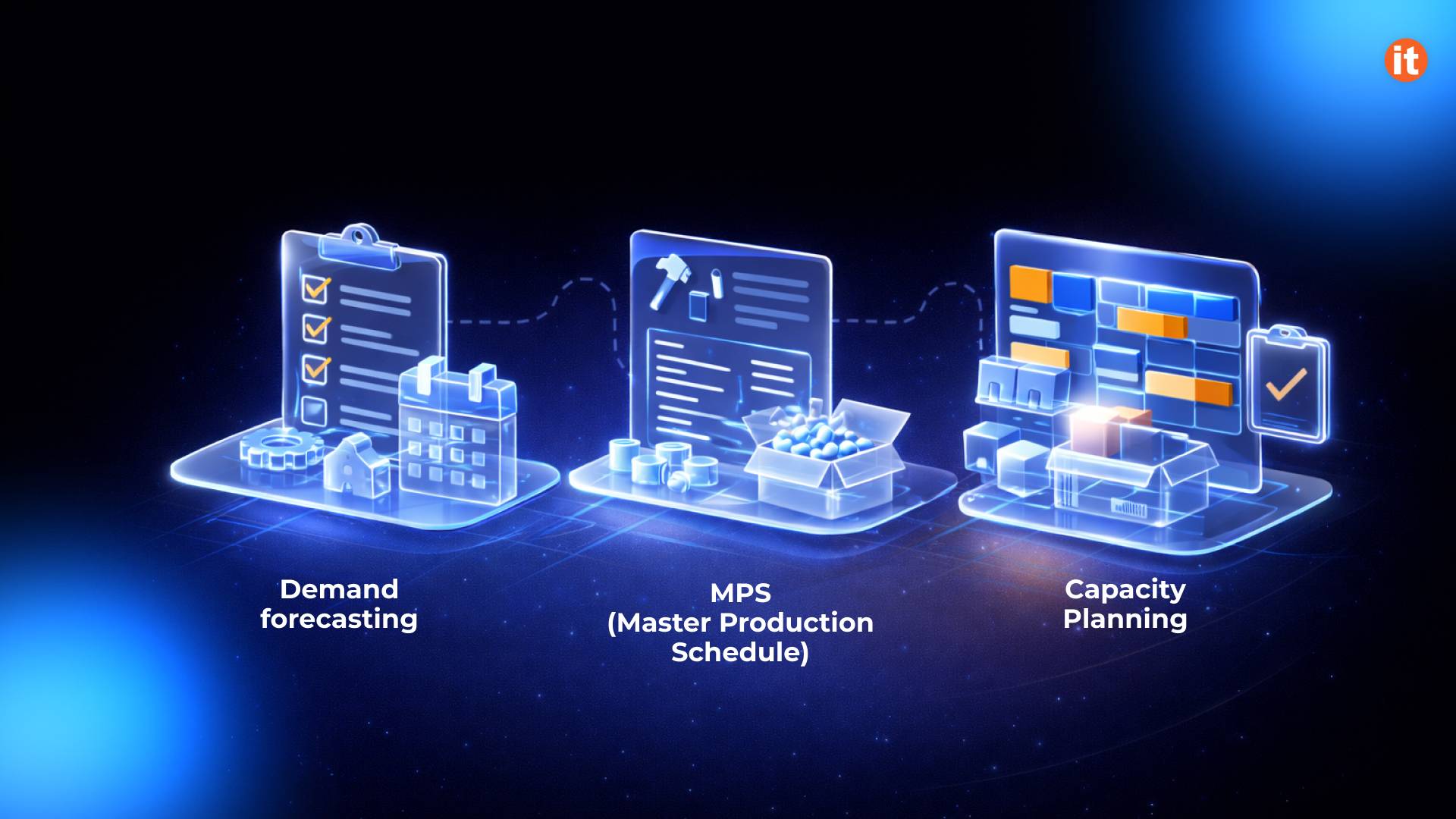

3 Main Types of Plans

- Demand forecasting

It’s a strategic middle-ground between the Demand Plan (what we think we will sell) and the Supply Plan (what we are capable of making).

- MPS (Master Production Schedule)

It’s a bridge between Sales and Production teams, a plan that tells the factory exactly what to build and when; sales know what to expect and sell to customers.

- Capacity Planning

It’s a check to see if MPS can be scheduled, it converts the production plan into standard hours of work, and detailed CP calculates the exact load for every department. It accounts for “setup times” (cleaning a machine between batches) and “run times.”

Manufacturing execution and production floor execution

This is where the plan is executing. It is often managed via a Manufacturing Execution System (MES) or a Production Floor Execution in Dynamics 365 Supply Chain Management.

Ensuring Planning Success by Including all aspects of manufacturing

The master plan is a complicated and detailed subject, yet it is responsible for everything your factory does. Ensuring flawless work, the ERP must support multilevel planning, warehousing management, and financial control. Starting from the primary component that consolidates everything:

Master Planning module in Dynamics 365 Supply Chain Management

Although manufacturing rarely goes exactly as planned. Considering this, the most significant part of any planning is adaptation to deviation. Action messages immediately show bottlenecks after the plan is recalculated.

Response to Planning Deviations via Action Messages

These are automatic system recommendations generated during the plan calculation by comparing the existing supply with the actual demand. If the terms or quantities in already created orders do not match the new needs, the system generates an action:

Concepts that Make Master Planning Work

Dynamics 365 streamlines master planning by utilizing Coverage Groups and Codes to define specific replenishment rules for individual items, for example, grouping demand by Period, generating orders for every single Requirement, or maintaining safety levels through Min/Max logic. To ensure these plans are executable, the system factors in precise Lead Times, calculating exact start dates for production or procurement based on vendor delivery speeds and machine run times. This operational framework is further enhanced by Demand Forecasting, which leverages historical data and Azure Machine Learning to predict future sales, providing high-intelligence input that keeps the entire planning process aligned with anticipated market trends.

The module supports three specific strategies:

Achieving Instantaneous Market Response via Planning Optimization

The integration of these advanced planning tools transforms supply chain volatility into a distinct competitive advantage. By leveraging Planning Optimization, businesses achieve unprecedented Operational Speed, moving from relying on stale nightly reports to a model that enables them to react to market shifts almost instantaneously. This agility is paired with high-precision resource management that minimizes inventory leftovers, ensuring capital is not tied up in materials that are no longer required. Ultimately, these capabilities ensure the organization can consistently fulfill customer commitments by providing early visibility into potential delays, allowing for proactive resolution before they impact the final delivery.

MRP & MPS: a significant part of the Master Planning in Dynamics 365

MRP (Material Requirements Planning) is a system designed to help manufacturers manage inventory, plan production, and ensure materials are available when needed. Its primary goal is to answer three critical questions: What is needed? How much is required? When is it needed?

It includes:

Core Material Planning Functions

Additionally, there are several important functions in Dynamics 365 that are part of the master planning module but work solely with material planning.

Planned Order: Fill the Gaps in Materials

Planned Order acts as a proposal generated by the Master Planning engine. It represents the system’s mathematical conclusion on how to best bridge the gap between your current supply and future demand. There are three primary types of planned orders, each serving a specific supply chain function: Planned Purchase Orders, Planned Production Orders, and Planned Transfer Orders.

The critical bridge between these suggestions and actual execution is firming. Firming is the administrative act where a human reviewer validates and approves a planned order. Once a planned order is firmed, it is converted into a document that then triggers the formal procurement or manufacturing workflow.

Demand Driven Material Requirements Planning: where the forecast doesn’t work

DDMRP has been proven in environments where customer tolerance times are shorter than the cumulative lead times required to make the product, or market demand is highly volatile or difficult to forecast accurately.

DDMRP moves away from purely forecast-driven planning. By establishing buffer profiles for decoupling points, the system ensures you order only what is actually consumed or needed based on real-time buffer status. And buffers are designed to cover average daily usage plus demand spikes, keeping stock at optimal levels even when lead times are long.

Explosion of a BOM: Foundation for Production Costing

It ensures that demand is not just recognized for the final product but is translated into specific purchase orders for raw materials and production orders for sub-assemblies. It allows the system to calculate lead times for every level of the BOM. By exploding the BOM, the system knows that if a finished product is needed on Friday, the sub-assembly might need to be started on Wednesday, and the raw materials ordered two weeks prior.

Since a BOM explosion defines every resource required to build a product, it forms the basis for estimating production cost when combined with the production route.

Where the Plan Meets the Plant

While the master plan provides the strategic roadmap for production, its success is entirely dependent on the physical accuracy of the warehouse floor. To maintain this “single source of truth,” the system transitions from abstract calculations to real-time asset control through the Inventory Management module, where the theoretical plan meets physical reality.

Inventory Management module in Dynamics 365 Supply Chain Management

Quality Management & Tracking

To ensure operational excellence, materials must be rigorously verified before entering the production cycle. Dynamics 365 automates this through Quality Orders, which trigger mandatory inspection tasks as soon as goods arrive from a vendor. To prevent the accidental use of unverified components, Quarantine Management allows the system to “block” items in a restricted status until the quality team provides formal clearance. Furthermore, the system maintains comprehensive Traceability via Batch or Serial Numbers; this functionality is a cornerstone of effective cost control, as it enables manufacturers to trace defective raw materials directly to the specific finished products they are used in, thereby mitigating the scope of potential recalls.

Managing Dynamic Inventory in Real-Time

The system transforms inventory from a static ledger into a dynamic, real-time asset by tracking constant movements through specialized Inventory Journals, including Movement, Adjustment, Transfer, and Counting Journals. For high-volume operations, the Inventory Visibility Add-in provides a high-performance microservice that tracks “on-hand” stock across multiple channels and locations with sub-second latency. This creates a Global View and a single source of truth, ensuring that the Master Planning (MRP) engine never makes critical procurement or production errors based on outdated or inaccurate stock data.

Measurable Impacts

The Strategic Importance of Transfer Orders

While a Transfer Journal is a simple “on-paper” move between bins or nearby locations, a Transfer Order is essential for any business that requires formal shipping and transit tracking. Unlike journals, transfer orders utilize the Transit Warehouse. This is vital because it ensures that while goods are on a truck or ship, they are not “lost” in the system. They remain on the company’s books, hard-reserved against the order, and are blocked from sale or use elsewhere until they are formally received at the destination. The transfer order process creates a clear “three-step” audit trail (Pick -> Ship -> Receive). This prevents the common problem of “phantom inventory”.

For companies using Warehouse Management Processes, transfer orders are indispensable. They allow warehouse staff to use mobile devices for picking, packing, and shipping, just as they would for a sales order.

From Tracking to Task

While Inventory Management provides essential data on your assets and their quality status, the Warehouse Management module acts as the engine that controls how those items are physically handled. This shift moves the organization from passive tracking to active coordination, turning inventory visibility into rapid movement through guided workflows and advanced automation.

Warehouse Management Module in Dynamics 365 Supply Chain Management

This module provides a highly flexible framework to manage every aspect of a warehouse facility. It is not a standalone tool but is fully integrated with other core business processes, including: Transportation & Logistics, Manufacturing & Production (supplying raw materials and receiving finished goods), Quality Control, Purchasing, Sales, and Returns.

Key Features & Capabilities

Dynamics 365 Supply Chain Management streamlines warehouse operations by utilizing sophisticated Inbound and Outbound Workflows, where “Work Templates” and “Location Directives” coordinate the precise movement and storage of each item. This is enabled by native Mobile Device Integration, allowing floor staff to use the Warehouse Management mobile app for real-time scanning, picking, and receiving, which eliminates delays caused by paper processes. To maximize throughput, Wave Processing automatically groups orders into efficient batches, while Advanced Picking and Packing features—such as cluster picking and automatic containerization—enhance the final stages of fulfillment.

Rigorous Inventory Control is maintained through detailed volumetrics and full traceability via batch and serial numbers, ensuring the system respects physical stocking limits. Finally, the inclusion of Cross-Docking capabilities allows high-priority items to bypass long-term storage entirely, moving them directly from receiving to shipping to accelerate order cycle times.

Core Benefits

MRP influence on cost control

Implementing a modern MRP system offers transformative benefits that directly impact a company’s competitiveness, primarily by driving operational efficiency and financial clarity. Ultimately, by automating the granular tracking of materials and labor, manufacturers gain a transparent, real-time view of their cost control, allowing them to protect their profit margins with data-driven precision.

Closing the Loop: the Ultimate Planning Auditor

It involves managing resources (labor, materials, equipment) effectively to minimize costs while maximizing output and quality. Although cost control is only effective when integrated with corporate planning systems. This allows “Work-in-Process” (WIP) information to be used to make immediate adjustments.

The module responsible for cost control in Dynamics 365 is Cost Management.

Cost Management in Dynamics 365 Supply Chain Management

Cost Management in D365 SCM is designed to value and account for raw materials, semi-finished goods (WIP), and finished products. It bridges the gap between the operational world and the financial world.

Dynamics 365 Supply Chain Management supports a range of Key Valuation Methods tailored to complex manufacturing needs. Organizations can utilize Standard Costing, which employs fixed costs set by the company to measure performance against an “ideal” baseline, or opt for Actual Costing models—such as FIFO (First-In, First-Out), LIFO, or Weighted Average—to reflect the real-time impact of price fluctuations. Furthermore, the system utilizes Costing Versions, allowing managers to maintain “Planned Costs” for risk-free financial simulations while simultaneously running “Active Costs” for precise, real-time accounting.

The power of Cost Management lies in its reports

These technical capabilities translate directly into Strategic Business Benefits, most notably by providing granular Visibility into Profitability. By tracking costs in real-time, leadership can distinguish between high-margin products and those losing money due to hidden operational expenses. Ultimately, this integration drives superior Inventory Accuracy, eliminating the risks of manual Excel-based tracking that often lead to “phantom” profits or devastating year-end financial discrepancies.

The Unified Manufacturing Loop

Microsoft Dynamics 365 Supply Chain Management stands out as a market leader by offering specific capabilities that address the most complex challenges of modern supply chains.

Integrating AI and Copilot provides predictive insights that help managers identify risks and optimize inventory levels through machine learning. The system’s Product Information Management (PIM) foundation offers unparalleled flexibility for complex product variants.

At the same time, its native integration with the broader Microsoft ecosystem ensures that financial cost control and operational planning are perfectly synchronized.

Last but not least: Interconnected aspects of planning and cost management

Planning, inventory management, and cost control form an inseparable triangle; if one side fails, the entire business structure collapses.

Planning provides the vision, but it is entirely dependent on inventory management for accurate, real-time data; if the warehouse records are wrong, the MRP engine will trigger the purchase of unnecessary materials or, worse, fail to order a critical component, bringing production to a standstill.

Conversely, even the most efficient warehouse is useless without a plan to guide the flow of goods, leading to “dead stock” and wasted shelf space. Tying these operational steps together is cost control, which acts as the financial auditor of the relationship. Without integrated cost tracking, a manufacturer might successfully plan and move goods through the warehouse but fail to realize they are doing so at a loss due to hidden overheads or material variances.

Therefore, these three functions must work as a single, synchronized loop: planning sets the targe Inventory management executes the physical movement, and cost control analyzes the results to refine the next plan, ensuring the factory is not just busy, but profitable.