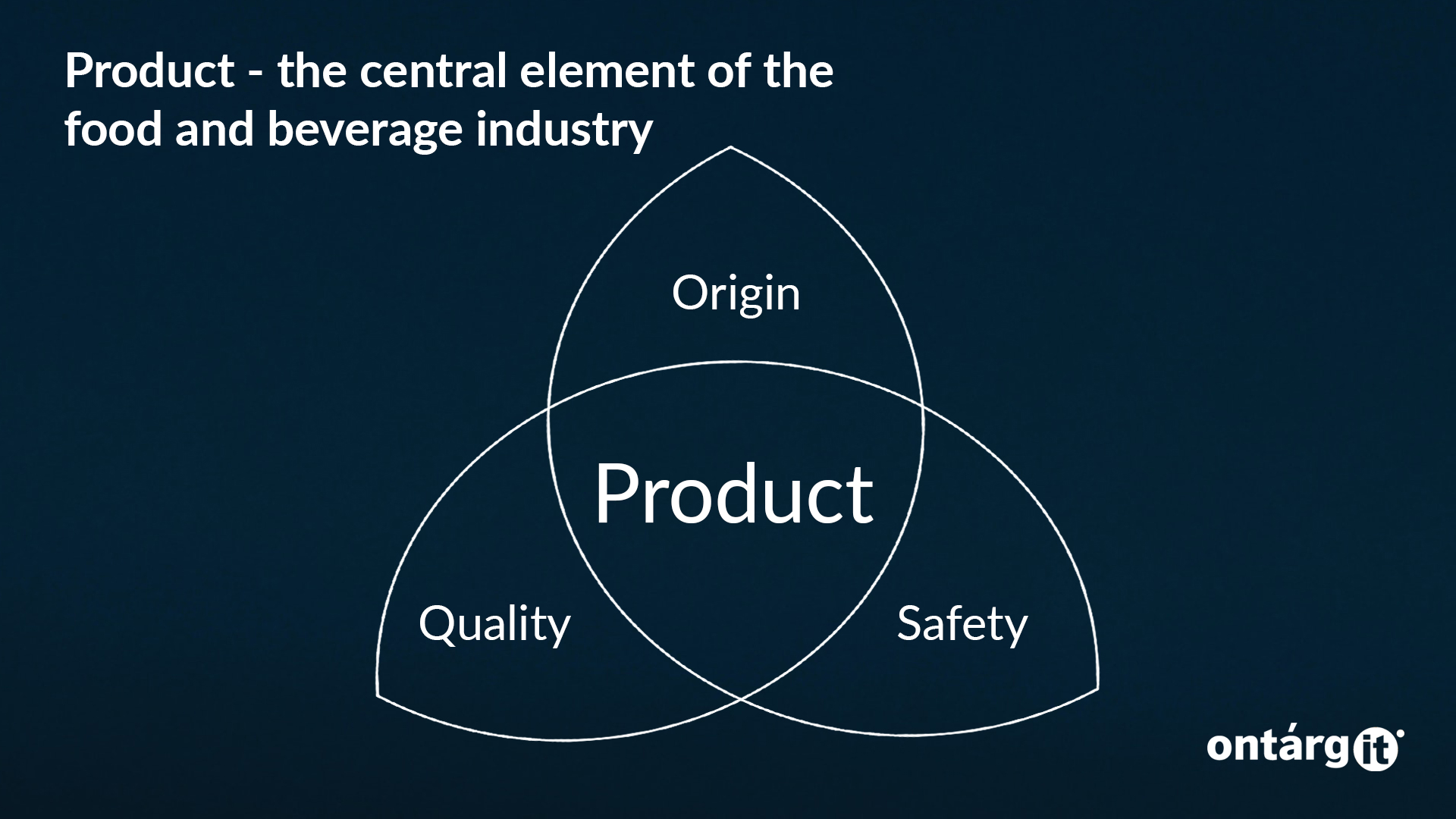

Running business in food and beverage industry requires fitting a combination of certain factors. The most important are quality, safety and profitability standards and each of them sets you a variety of additional tasks full of nuances and requires a unique solving method.

In order to stay efficient, a modern enterprise requires a cutting-edge technology to meet market development speed. During the last few years enterprise resource planning systems (ERP) had become a golden standard to achieve a flexibility and create new ideas to improve the competitiveness of the business.

Let’s review some of the most important challenges for the food and beverage industry.

Real-time inventory process and supply management in ERP for Food and Beverage Industry

It might seem obvious but knowing up-to-date information you can rely on might play a crucial role in creating competitive advantages in food and beverage industry.

ERP-systems, created specifically for the manufacturers in this specific market, use integration and automatization features to give the ability to display exact amount of supplies you have in stock. Also, ERP-systems gather more data in order to facilitate the search for the information you require – you can find any information about shipment status, due date or else on each consignment you have in your control.

Formula and recipes control

Recipes hold a great importance for your products success, so for keeping them in order you need reliable tools to guarantee the accuracy of the procedures, ingredients amount and much more. In some sectors of food industry chemistry formulas records might be complicated, but with correctly chosen ERP-system even the trickiest features will be put under consideration.

Automatic unit conversion feature in Food and Beverage ERP is mandatory – it saves a lor of time when you need to adjust and control money flow. Besides that, you should choose a system that have an integration with smart sensors to control temperature, consistency, filling level and other indicators which affect the quality of your product.

Shipments tracking

ERP system collects all important data related to your ingredients supply, so you can track and identify all possible damaged goods and where they were used.

The system collects all the important data related to your ingredient batches so you can identify where your problem materials came from, in which products they were used in your facilities, which production lines they may have interacted, and where the affected products are going.

Allergen control

Let’s see how to deal with the most widespread causes of allergen contamination.

At this phase of production in order to ensure the safety of all the products you manufacture and to keep up with all standards of data and allergen management, you need to use industry-leading ERP software to maintain all required documentation for your business.

Batch tracking

Business must have an ability to control ingredients and supplies at all production stages in bi-directional tracking. Batch tracing helps the manufacturers to identify where the ingredients in a particular batch came from and where it went afterwards. Features of versions control provide an ability to overview history of recipes usage for every batch, so you access a log of all original batches of ingredients that were used at specific time and place.

In the case of a product recall, such information is needed to perform a targeted recall, such feature is available in a specialized software. If a supplier realized that a batch of, for example, spice mix contained walnuts, the ERP system can track where and when this specific batch was used and how much of it, and then will provide an information about where the finished product went.

Specialized Food and Beverage ERP

Main functions

A specialized Food & Beverage ERP system brings materials, semi-finished products, products and all their variants together to for the customer’s demands and as the result requested quality can increase your productivity. Such features of the ERP system provide flexibility in any type of planning, which makes whole process much more dynamic.

Therefore, by choosing a specialized Food and Beverage ERP solution, you will get the main advantages of an ERP system adjusted for your industry – functions developed specifically to control quality and origin of your supplies and products, ability to work with several units of measurement and their conversions, also up to date tracking movement of materials starting from the supplier and control the variety of not only of the same type of materials, but also of their various extended attributes.